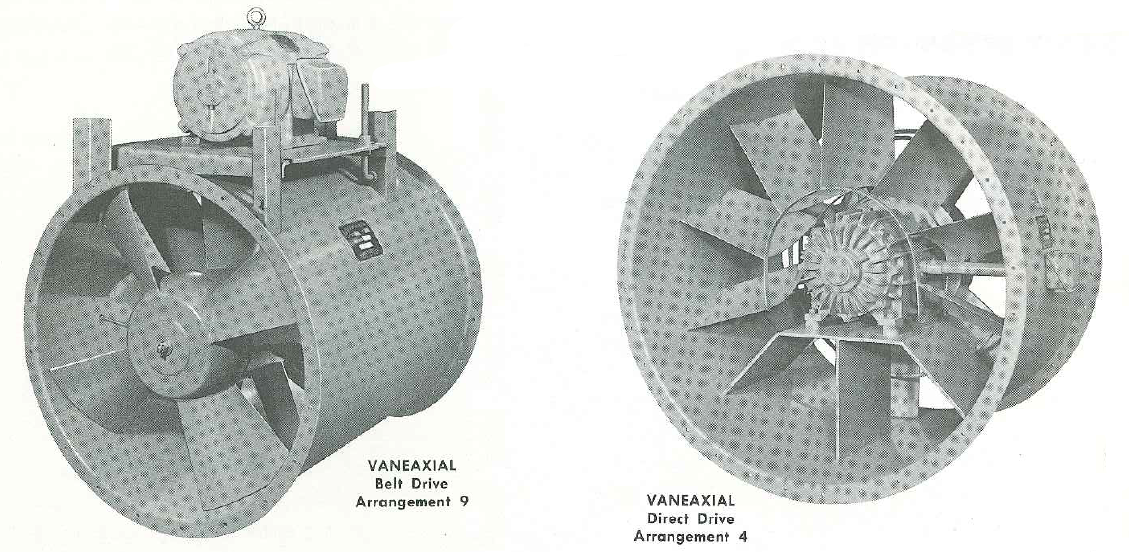

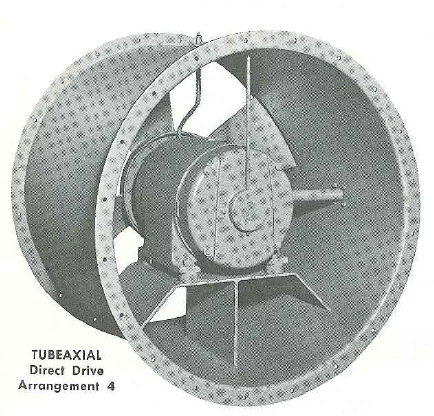

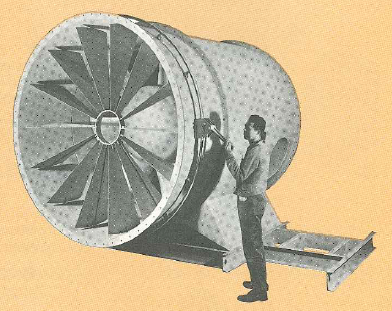

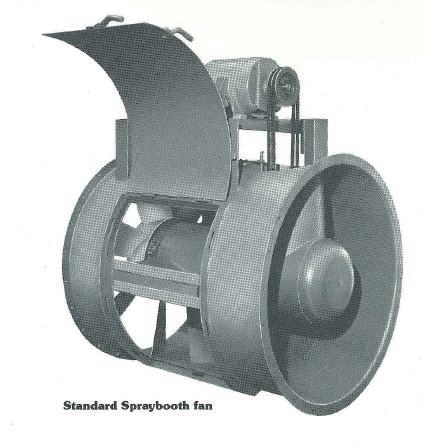

- 3000 CFM to 400,000 CFM capacity range.

- 1" to 17" Total pressure Capability in single stage units.

- Up to 81.5% Total Efficiencies.

- 13 Fan Sizes.

- 22" through 84" Wheel Diameters.

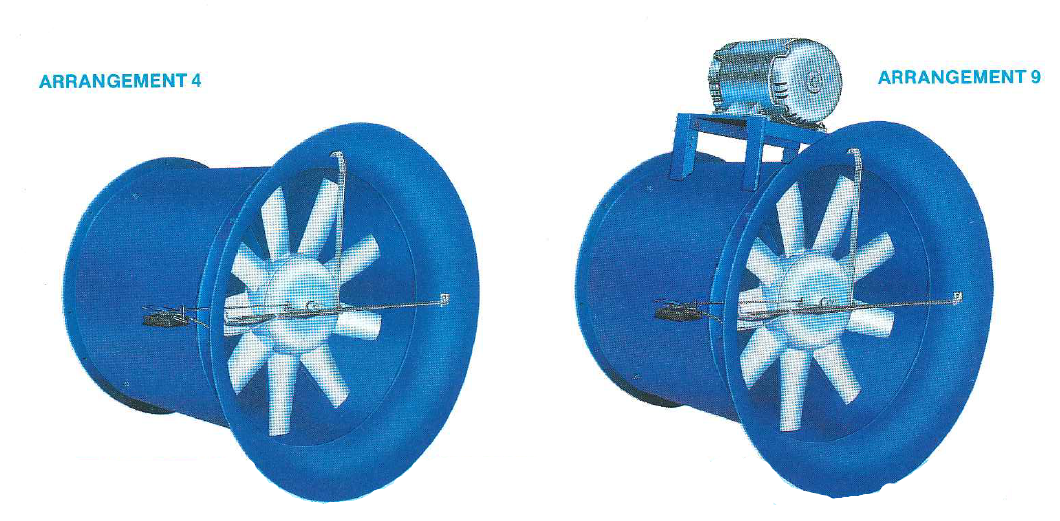

- 98 cataloged DIRECT DRIVE fan and motor combinations.

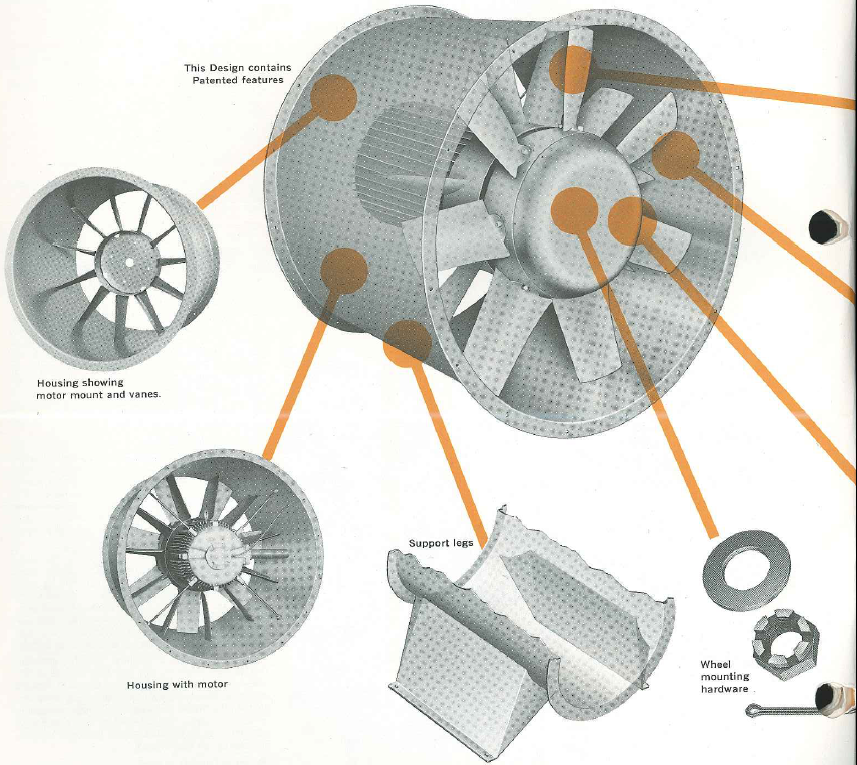

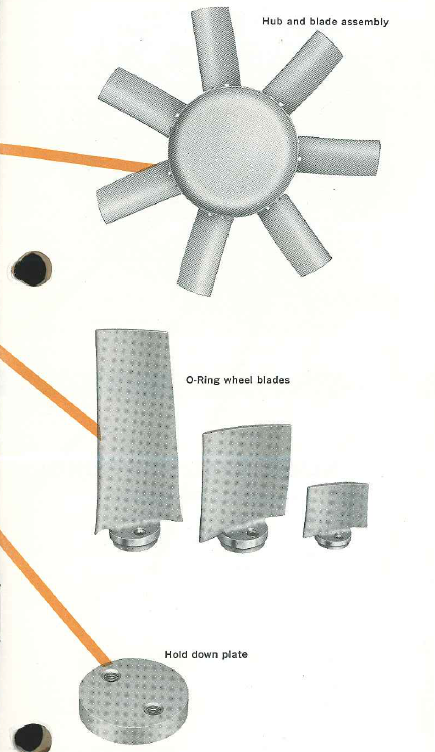

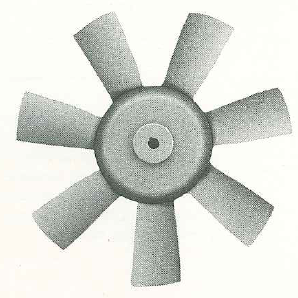

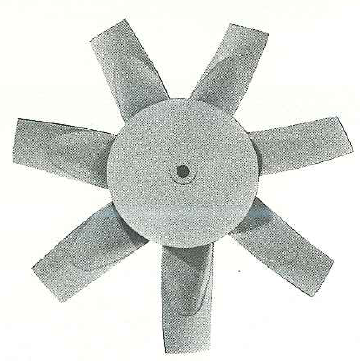

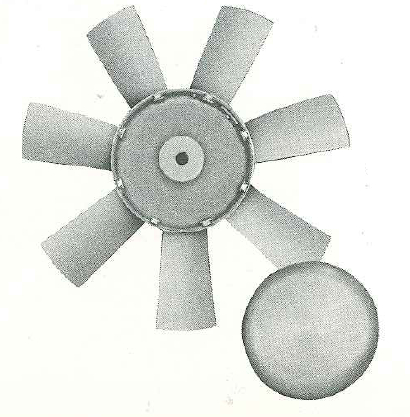

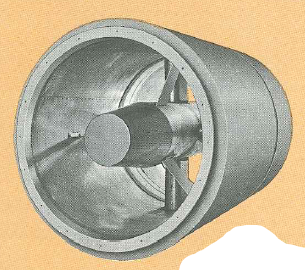

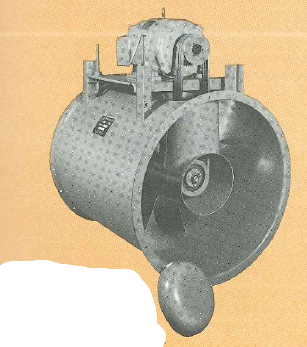

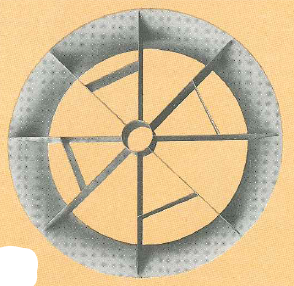

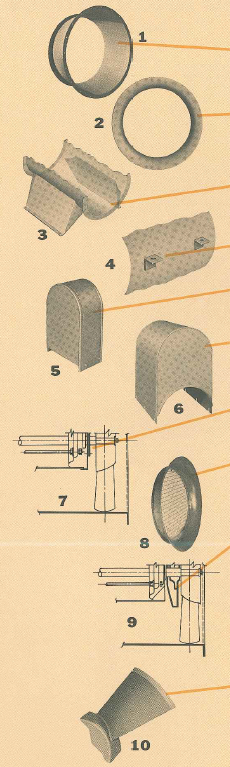

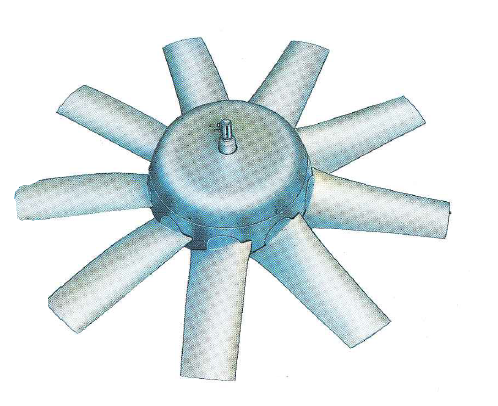

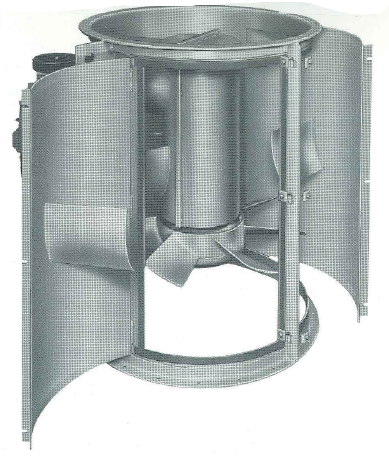

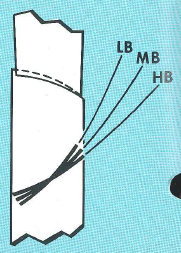

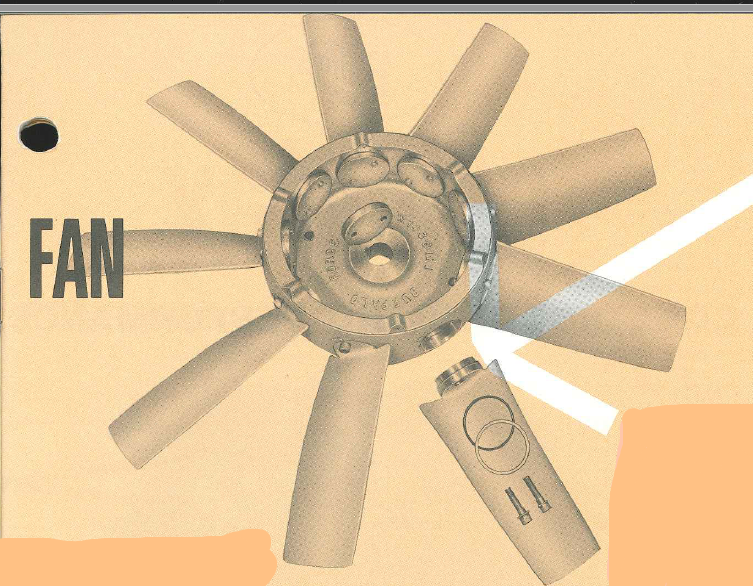

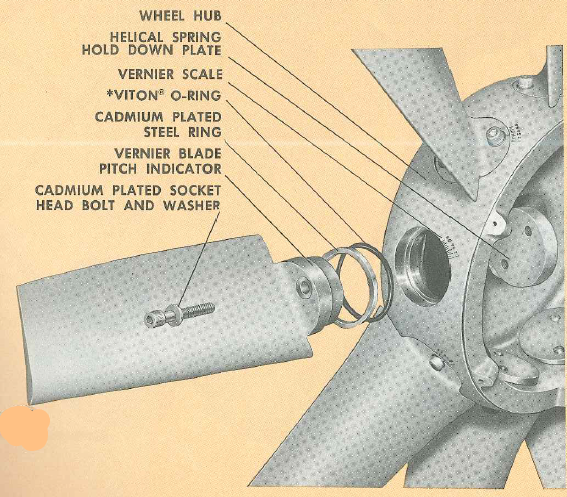

EXTERNALLY ADJUSTABLE O-RING BLADES

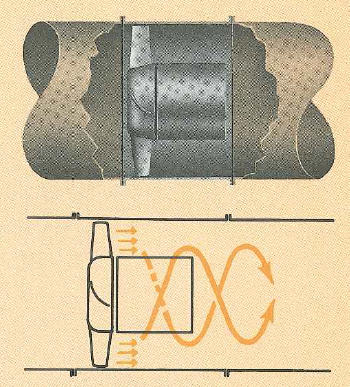

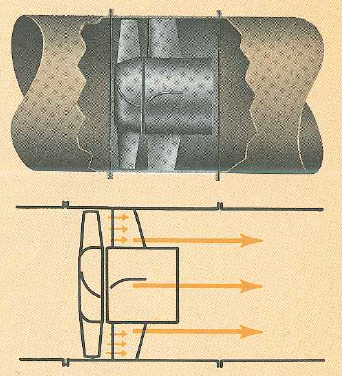

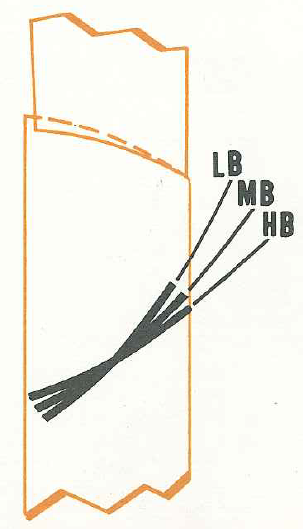

The Adjustax O-Ring blade provides the ability to custom set blade positions without removing the wheel and/or nosepiece to provide maximum efficiency for specific requirements and the flexibility to field adjust for known future needs and/or balance systems with the minor corrections often needed for the unpredictable installed system variations. This versatility and longer life without complexity, special tools or excessive cost are exclusive (patent pending) with Canada Blower

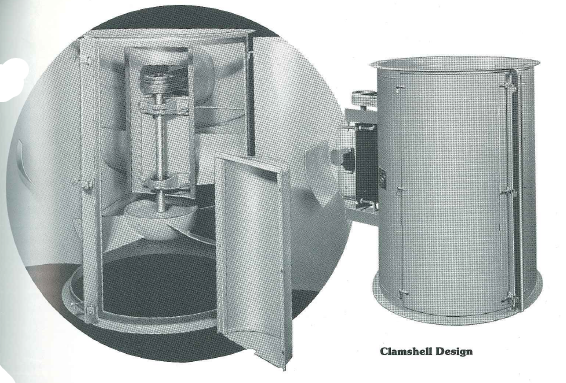

The O-Ring blade design provides adjustability without disturbing the structural integrity provided by the factory-torqued, blade attaching bolts. The blades are hand adjustable from the fan inlet or, for ducted inlet installations, a blade access door in the fan housing can be furnished along with a simple socket wrench tool to conveniently grip the blade for hand adjustment. After adjustment, it is not necessary to RPB-torque the blade attaching bolts.

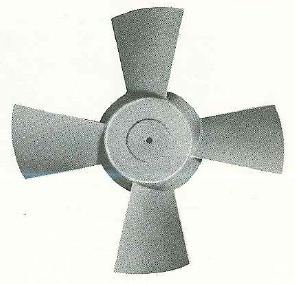

Although the blade can be intentionally turned by hand, it will not inadvertently turn in actual operation. When the wheel is at rest, the torque on the blade attaching bolts is calibrated to prevent all but intentional blade adjustment. When the wheel is in rotational operation, the friction between the blade and wheel hub is increased by centrifugal force holdingthe blade steady to prevent any change in blade setting. The O-Ring is made of resilient *VITON® material. This durable material will last the lifetime of the wheel while serving as a vibration isolator to dampen the transmission of the air and mechanical vibrations between the blades and wheel hub. Since vibration is the chief cause of material fatigue, this reduction of vibration results in substantially increased useable lifetimes for all applications.