BACKGROUND

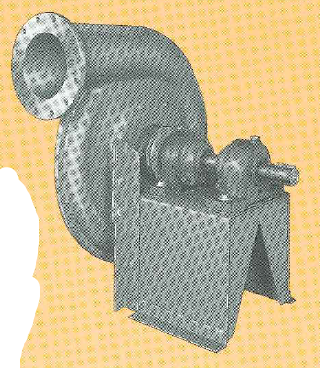

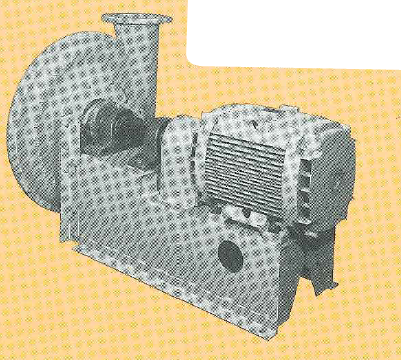

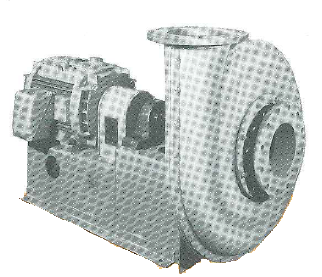

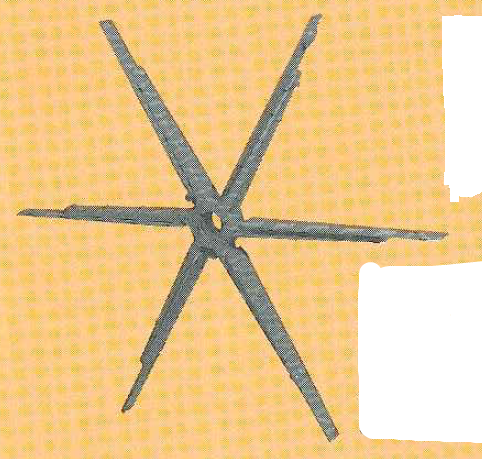

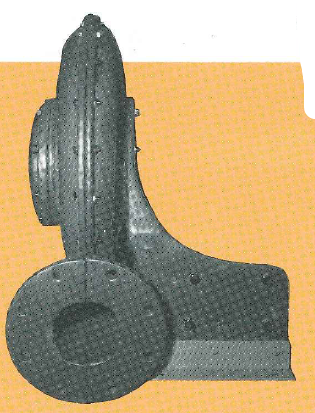

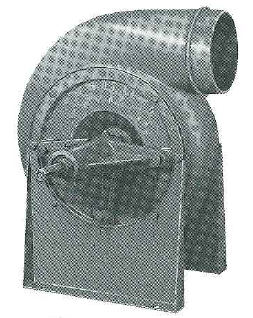

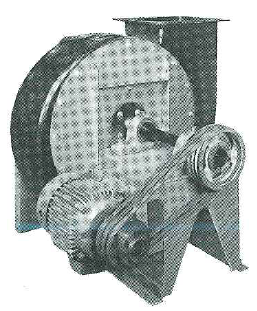

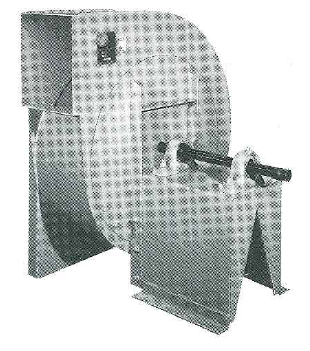

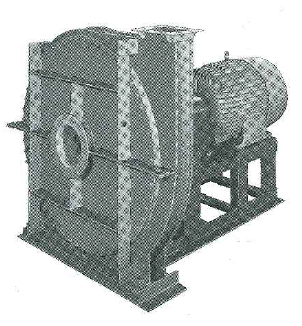

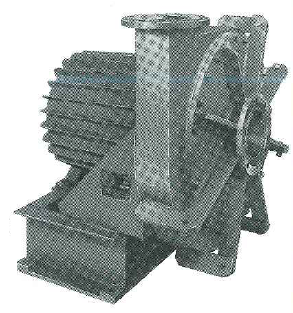

Every industry has the need for rugged, reliable, yet economical blowers and exhausters capable of handling up to 10,000 cfm at medium to high constant pressure. “PE” & “RPB” Blowers and Exhausters fulfill this requirement. Seventeen models and a wide range of accessories and special construction options have been developed over the years. Most air handling jobs which fall within the 50 cfm to 10,000 cfm range, at pressures up to 83" S.P., can be handled with an “PE” or “RPB” Blower or Exhauster.

APPLICATION

“PE” and “RPB” Blowers and Exhausters are widely used in the chemical process industries, primary metal, foundry, glass and metalworking industries, by original equipment manufacturers as well as in general manufacturing. Typical applications include: paper manufacturing & processing, hood or tank exhaust, combustion air for oil or gas furnaces, cupola work, grinding or buffing machine exhaust, air curtains, paper drying, ink drying, tank & vapor exhaust, and other air pollution control applications, engine & motor cooling, fluid bed aeration, metal, wood & plastic conveying, structure inflation, pneumatic conveying, gas boosting plus dozens of similar air or gas moving jobs. “PE” & “RPB” Blowers and Exhausters are also used as components on equipment and systems designed and manufactured for resale.

THE DIFFERENCE BETWEEN “PE” AND

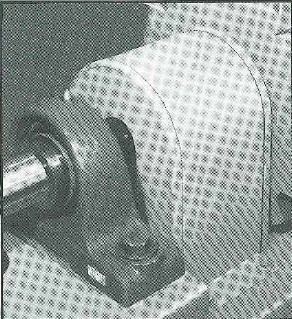

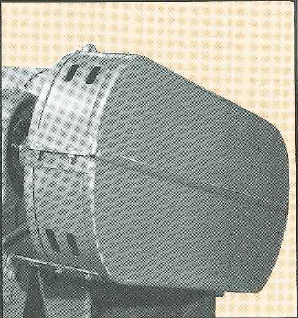

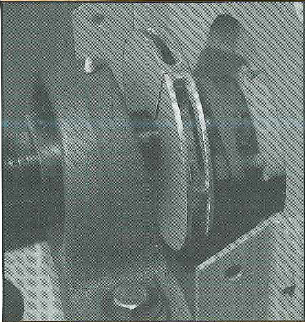

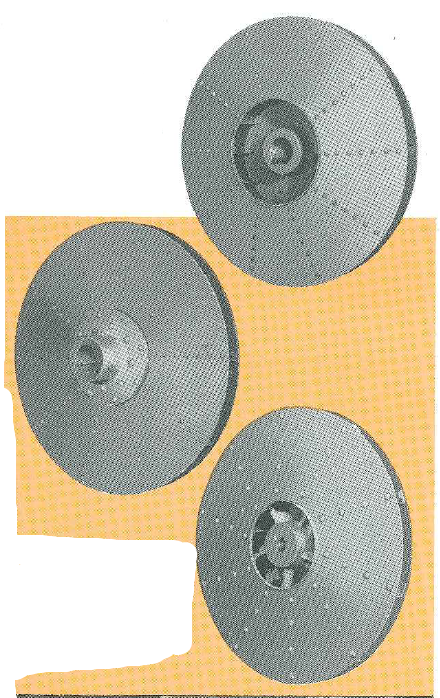

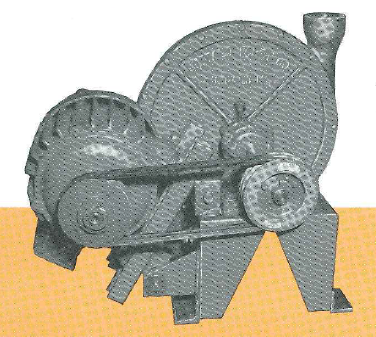

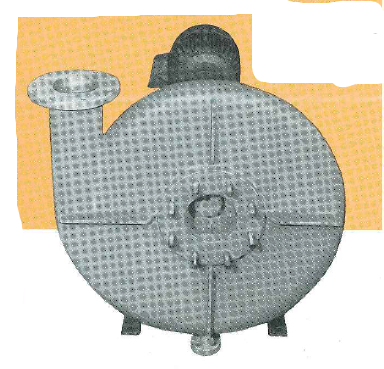

“PE” & “RPB” Blowers and Exhausters are similar in design and construction. Both are available with fabri-cated steel (F.S.) or cast iron (C.I.) housings. The differ-ence, generally, is that the “RPB” models provide higher pressures and lower volumes, while the “PE” models pro-vide higher volumes at lower pressures. There is some overlap in ratings. A Sales Engineer will RPB-commend the correct unit for your specific operating conditions.

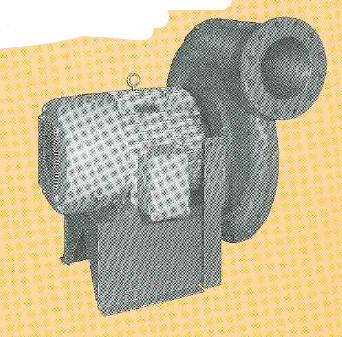

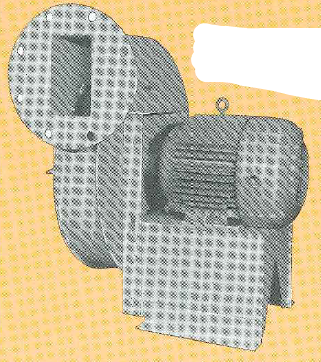

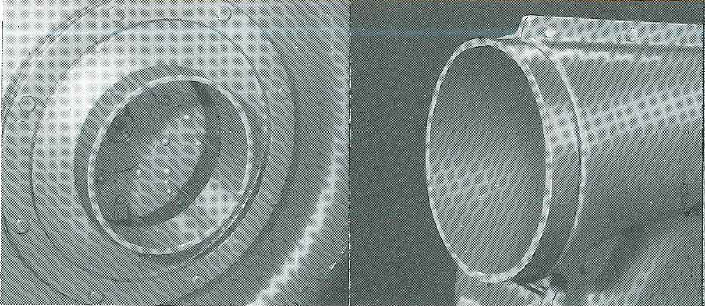

CAST IRON (C.I.) VERSUS FABRICATED STEEL (F.S.)

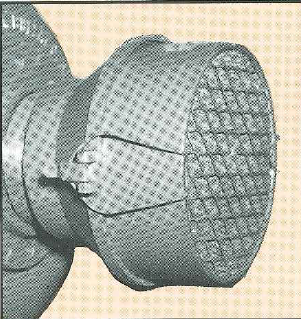

Housing material selection is based on operating condi-tions and, to some degree, on cost. Cast iron (C.I.) units

are of a heavier, more rugged construction. They are inherently resistant to erosion, and trace amounts of corrosives. Cast iron (C.I.) “PE” & “RPB” Blowers and Exhausters are somewhat quieter in operation. Fabricated steel (F.S.) housings are more economical, and lighter in weight for easier installation. Horsepower consumption of fabricated steel (F.S.) units is slightly lower for a given CFM and pressure. For corrosive environments, “PE” & “RPB” Blowers and Exhausters in special metals, fiberglass, or with special coatings, are usually the correct choice. Consult with your Sales Engineer on specific construction based on your operation conditions. A full line of accessories and special features is available for each type of construction.

ENGINEERING ASSISTANCE

Forge provides the most complete selection of fans and blowers engineered and manufactured for industrial service. “PE” & “RPB” Blowers and Exhausters cover a range of capacities, pressures and operating conditions detailed in this Bulletin. For system requirements outside the scope of the “PE” & “RPB" line, offers Industrial Exhausters, Volume Fans and "CB” and “R” Pressure Blowers (see back cover of this Bulletin). Series “H” and Series “L” Heavy Duty Fans meet the demanding requirements for high capacities and pressures for such applications as industrial boiler draft, air pollution control systems, and large kiln or drier service.

Selecting the correct fan or blower to meet specific oper-ating conditions requires a thorough knowledge of air handling. The Sales Engineer in your area has this knowledge. He is a graduate engineer who has successfully completed s in-house engineering training program. He is fully qualified to help you select the Fan or Blower needed for your application. He has, at his disposal, ’s computer-based fan selection programs. These programs cover industrial fans and blowers, and may be used simply to select a special wheel diameter for an “PE” Blower or to optimize selection among several fans for a large industrial coal fired boiler. You can rely on this combination of Sales Engineering Representation and computer back-up to provide the engineering assistance you need to assure proper fan or blower selection and application.