frp

FIBERGLASS

designed, engineered and built

FRP OFFERS THE ADVANTAGES OF FIBERGLASS REINFORCED PLASTIC CONSTRUCTION

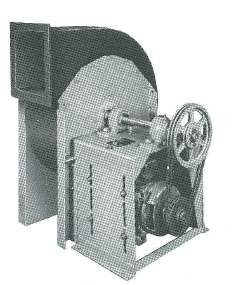

FRP (fiberglass reinforced plastic) construction is receiving increasing recognition for its many advantages in handling corrosives. Primary is the extension of service life many times that of ordinary materials at costs much less than those of stainless steel, special metals and coatings. In addition, impact resistant housings are electrically non-conductive and fire retardant.

While these and other advantages of FRP construction are now available in air handling equipment, it is most important that this equipment be basically sound in design and engineering, as well as in correct selection and application, to render effective, efficient and economical performance.

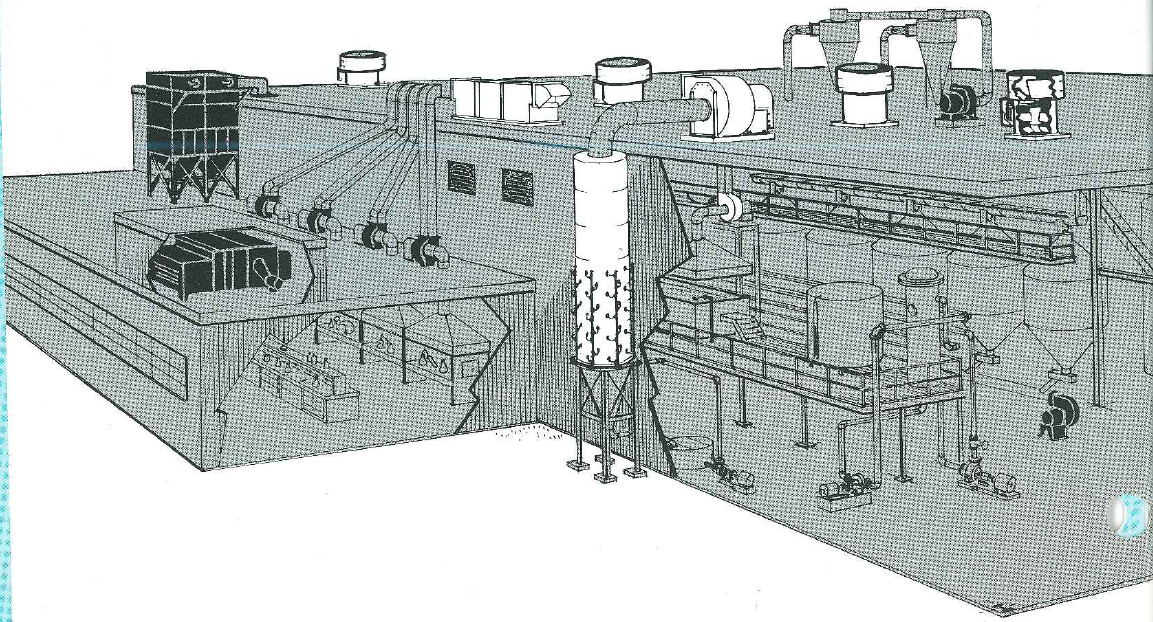

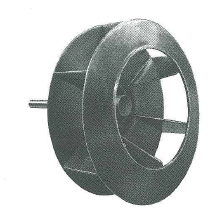

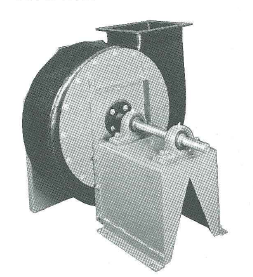

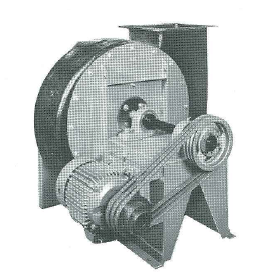

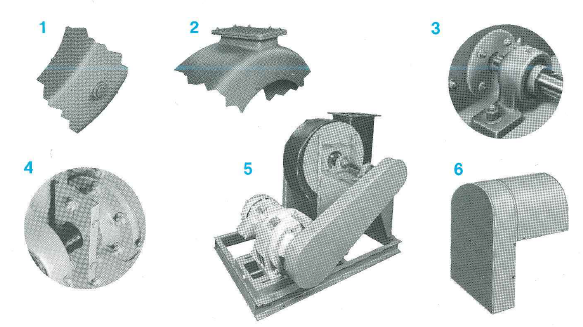

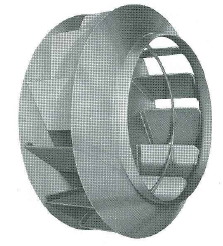

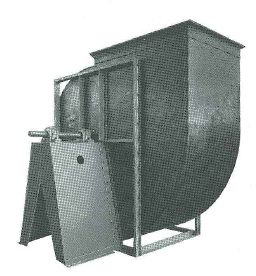

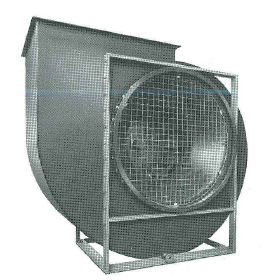

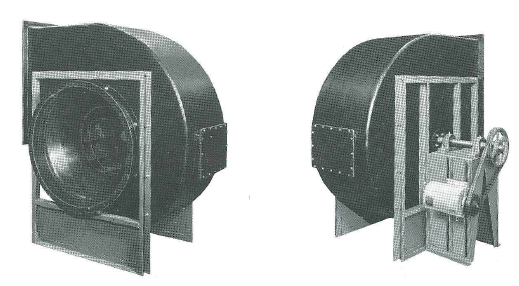

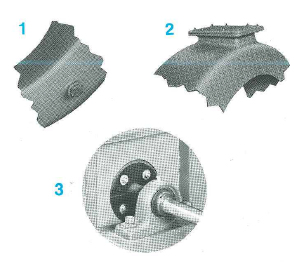

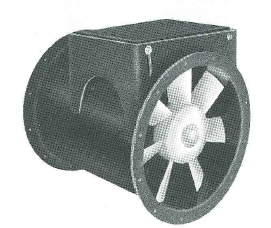

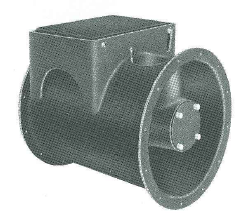

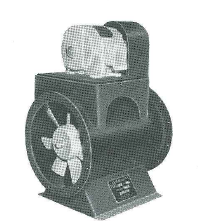

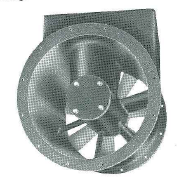

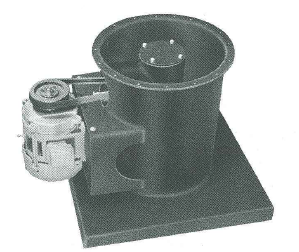

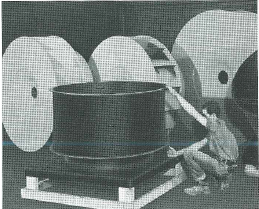

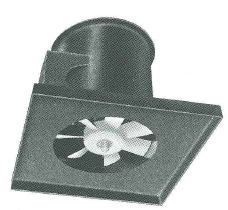

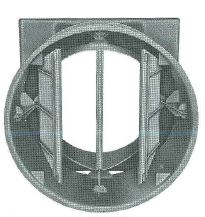

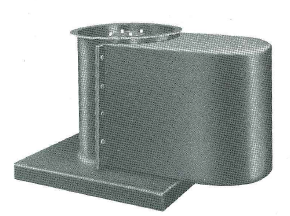

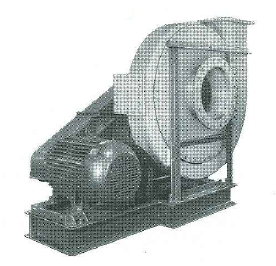

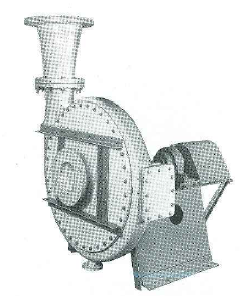

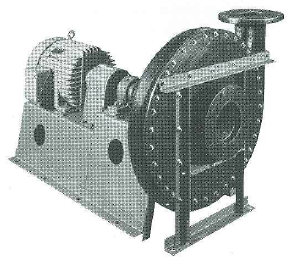

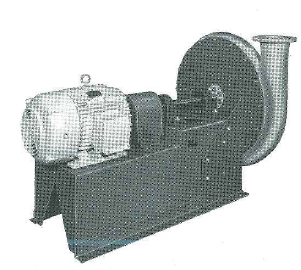

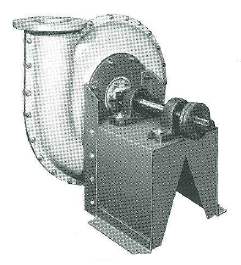

FRP air handling equipment is now available in a comprehensive line including a variety of axial

fans, roof ventilators, centrifugal fans, exhausters, pressure blowers, ventilators and air cleaning units. These are pictured and briefly described in this bulletin.

The construction and design of each unit . . . based upon specialized air engineering experience . . . assures efficient and economical performance in its intended application.

Correct selection and application is further assured by air engineering specialists located in major centers throughout the USA and Canada. The recommendations of these men are confirmed and supported by the technical staff at the factories.